While I can understand the science behind this argument when dealing with CPU's and heat sinks with large surface areas (because lets be honest that argument involves more than the amount of paste but even the type and how it's applied), but when you're dealing with single junction transistors regardless of application I don't buy it for a second unless you have a detailed analysis indicating such that I can review?

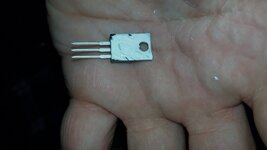

I will say that if the amount of paste being applied is so liberal you can't get the screw and nut together that's another issue altogether, but when it comes to reasonable amounts of paste for things like TO220 transistors, it's not that critical. (and from what I've seen here, Mitch hasn't gone overboard)

If you could explain to me how any amount of extra paste will remain between a TIP102 transistor and a heat sink when screwed together other than whatever isn't squished out filling the air gap between the two, I am all ears. Thermal paste is a fluid medium and will be displaced by the force of the screw clamping it to the heat sink, only leaving behind what can fit in the air gap which is determined by the physical space dictated by the heat sink and transistor surfaces.

D